在要求细致对待的技能、设计面的开发上,注意倾听并全力实现用户的每一个要求,因而获得了客户的广泛信赖

靖江市荣泰机械有限公司主要生产系列液压、机械联合冲剪机、系列液压(数控)摆式、闸式剪板机、系列液压(数控)板料折弯机、卷板机的专业公司。公司技术力量雄厚,工艺及制造手段精良,主要技术骨干具有多年的生产经验,企业并取得了ISO9001:2000质量体系认证和CE认证,并获得了出口机电产品质量许可证。本公司一贯致力产品开发和质量水平的提高,产品畅销40多个国家和地区,深受国内外客户的欢迎。

13901429350

13901429350

rt@jjrongtai.com

rt@jjrongtai.com

中文

中文

EN

EN

折弯机

折弯机 剪板机

剪板机 多功能联合冲剪机

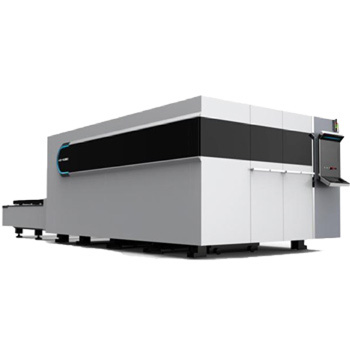

多功能联合冲剪机 激光切割系列

激光切割系列 刨槽机

刨槽机 卷板机

卷板机 冲切机

冲切机 公司动态

公司动态 行业动态

行业动态